News

Explosive report on hazards of Norochcholai coal power plant

The Lakvijaya coal power plant in Norochcholai does not have a valid ‘scheduled waste management licence’ as required by law for a facility that generates hazardous matter, says an explosive report by an organisation called the Coalition against Coal (CAC).

The campaign against coal is growing after the Cabinet recently sanctioned a new electricity policy that includes the generation of 30 percent of energy through fossil fuel. The approval came after President Maithripala Sirisena’s office asked the independent Public Utilities Commission of Sri Lanka (PUCSL) to approve the Ceylon Electricity Board’s (CEB) long-term generation plan that envisages multiple coal power plants. The regulator has resisted retaining coal power plants in the country’s long-term energy mix owing to, among other things, environmental concerns.

coal dust and fly ash: Open dumping is of significant concern

CEB insiders, including engineers, have dismissed opposition to coal as a conspiracy by the “LNG mafia” as there has been a recent push to diversify towards electricity generation through liquefied natural gas. Conversely, however, there are also allegations of the existence of a “coal mafia” and it is not immediately clear why one “mafia” would be better than the other.

Lakvijaya has also been operating since June 2017 without a valid environmental protection licence (EPL) which is issued by the North Western Environmental Protection Authority (NWEPA). Meanwhile, 74 shallow wells and eight deep wells have been built in the facility premises without the requisite approval from the National Water Resources and Drainage Board. This contravenes the stipulations of the Environmental Impact Assessment (EIA), CaC says.

Key modifications carried out by Lakvijaya also do not possess the necessary approvals from the NWEPA as stipulated by law; neither was the recent expansion of the coal yard cleared by the NWEPA. “This is despite coal dust blowing into the village being a very serious concern for the villagers,” CaC points out, “and the expansion towards the village increased the dust incidence.”

The Chinese-built Lakvijaya plant has posed multiple problems since its commissioning. The Coalition says that a significant number of elements in the EPLs issued by the NWEPA have still not been met by the plant but that the Authority has not taken any regulatory action in this regard.

“None of the other regulatory bodies including the Central Environmental Authority (CEA), Marine Environment Protection Authority (MEPA), Coast Conservation Department (CCD) or local Government has taken regulatory action on Lakvijaya plant despite ample evidence of violations,” it observed. “It is noted that, although the NWEPA has primary jurisdiction, CEA also has jurisdiction due to ocean pollution and trans-boundary migration of pollutants via stack emissions.”

The CaC has traced a litany of omissions by the Lakvijaya administration. For instance, contrary to EPL requirements, the plant does not have “properly functioning stack emission sensors”. Such sensors are important to determine the quality of emissions as these contain sulphur dioxide, nitrogen oxide and carbon monoxide.

“Examination of data recorded from the existing continuous emission monitoring system indicates that data is neither reliable nor accurate,” the Coalition says. “Lakvijaya is still to fix the problem although multiple reports have pointed out this issue.”

The sensors have not been put through Sri Lanka Accreditation Board (SLAB) accredited calibration which is an annual requirement. Visible fume emissions were also observed in a number of instances even when the electrostatic precipitator (ESP) was working. “The lack of properly-calibrated monitoring equipment does not allow recognition of such instances to take appropriate mitigation,” it points out.

“While it is critical to ensure the ESP and FGD (flue-gas desulphurizer) efficiencies, the plant lacks any means to measure the same,” it continues. “The pre-FGD sensors have design faults and are yet to be repaired to assess FGD efficiency.”

Major failures relating to FGD and ESP equipment are “routine” at the facility, CaC maintains. For instance, the ESP of Unit 1 has been malfunctioning at least from January 2018 until it was shut down for repairs under NWEPA orders in April. “This is a serious violation of the emission standards and the local law,” the Coalition asserts. “It was estimated that, during this period, approximately 150-200 tonnes of fly ash were released to the environment a day.”

Major failures relating to FGD and ESP equipment are “routine” at the facility, CaC maintains. For instance, the ESP of Unit 1 has been malfunctioning at least from January 2018 until it was shut down for repairs under NWEPA orders in April. “This is a serious violation of the emission standards and the local law,” the Coalition asserts. “It was estimated that, during this period, approximately 150-200 tonnes of fly ash were released to the environment a day.”

Between February and March 2018, the FGD of Unit 1 was not functioning for 24 days. It was also not operational from about October 2017 to January 31, 2018. “Each day the FGD of a single unit is non-functional, 37,000kg of sulphur oxides are released to the sky creating acidification,” it said.

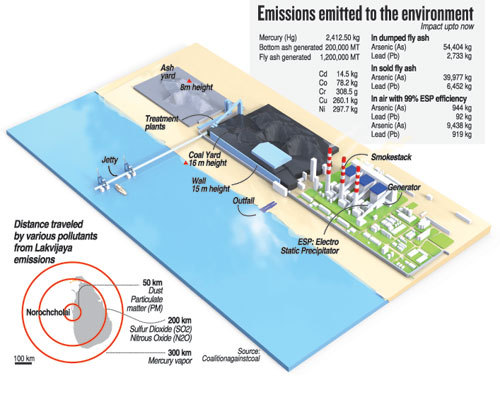

No proper investigation has been conducted by CEB or Lakvijaya to understand why these units are failing continually and to decide on suitable intervention, the Coalition alleges. Uncontrolled sulphur dioxide emissions create acidity in moisture and acid rain. Sulphur oxide emissions can travel far (up to 200km) and acidity poses a serious risk to Sri Lanka’s unique cultural and natural heritage.

The Coalition also warns the Lakvijaya does not have any protections against mercury pollution. None of the presently available mercury treatment processes–such as fabric filters, sorbent injection, activated carbon injection or wet FGD with lime (trapping it in gypsum)–is installed.

Meanwhile, an estimated 17,000 tonnes of coal are lost into the ocean due to spillage during unloading from ship to barge. It is common for coal pieces to get washed out to the beach as far as Kalpitiya. It is also estimated that over 50,000 tonnes are blown into the ocean and the village due to winds.

“Currently, the South African coal purchased by CEB has a very large amount of particles,” the Coalition said. “It is estimated that coal piles in Norochcholai have over 35% dust (particles less than 2mm) highly susceptible to win erosion.”

The yard was extended in 2017/2018, moving coal closer to the village. “At its peak, the coal yard stores 1.3mn tonnes of coal,” it pointed out. “A present, the coal yard is 360m by 450m, with coal stacked up to 16m high.” There is no provision in the coal yard to prevent leachate of coal dust to ground water from the sides of the yard, especially the side facing the village. This leachate will add toxicity to the groundwater aquifer.

The Lakvijaya power plant had also proposed a 15m semi-porous wind barrier costing Rs 720mn. This was put on hold due to serious concerns about design. When the coal yard is tacked at 16m, a 15m fence cannot serve as erosion protection, CaC says.

Fly ash open dumping is also of significant concern as the yard is open to wind erosion and leaching. “It is noted that 80 percent of fly ash is smaller than 10 microns,” it observes. “Even winds at one metre per second are capable of lifting them and blowing them away. Smaller sized particles raise significant health issues.”

Fly ash is high in heavy metal concentrations. According to CEB’s own test reports, arsenic and lead are released in dumped and sold fly ash. These have impact on human health. Fly ash emissions from the stacks also travel large distances before deposition and create heavy metal and particulate matter risk to multiple provinces including North Western, Northern and North Central.

“Approximately 1000 tons of fly ash are generated per day at Lakvijaya,” CaC states. “Although the CEB went through a Cabinet-approved tender process for 100 percent sales of fly ash in February 2018, the fly ash sales percentage today is still approximately 60 percent. This means dumping of over 400 tons of ash into the ash yard per day using open tippers and during the monsoon creating significant community pollution.”

The ash dumping yard is approximately 290m by 360m and eight metres tall. From late 2017, Lakvijaya has covered the ash yard with ash slurry to reduce airborne pollution. But only a part of the yard is thus covered, and other areas are open to erosion.

“There is no provision in the ash yard to prevent leachate of fly ash into the water table from the sides of the yard,” the Coalition points out. “In fact, there is significant fly ash pollution on the roads and surroundings of the facility that significant leachate is impossible to prevent.”

The correct method to operate a fly ash yard is with “high concentration slurry disposal”. The current level of open dumping, with little water mixed, raises significant fly ash pollution, risking community health, the ecology and CEB employees.

“Lakvijaya is planning to dig and sell the existing fly ash in the ash yard to vendors,” CaC reveals. “This process comes with significant pollution risk as it requires digging the existing yard, filling tipper trucks (both create additional airborne fly ash risk) and transporting them at the rate of 75 trucks per day. At present, the plant has no idea how to do this without creating further pollution risk.”

In June 2017, a petition signed by 71 employees of Lakvijaya complaining that the health of operation and maintenance staff was seriously compromised by dust and ash was sent to authorities. It pointed out that around 14 to 16 percent of total combustion is retained as ash.

There was a significant increase in the airborne ash particles around the silos. This is then carried towards the main power block with the wind. Conditions were much worse during the monsoon from April to October when dust was carried away from the silos and the yard towards adjacent villages.

The employees who work in close proximity to the main plant and yards are exposed to the dust throughout the year due to extensive, round-the-clock dumping. “Though the employees have been provided with dust masks, we have come to understand that only a fraction of the dust particles are filtered by these masks due to the nature of the particulate matter,” the letter stated. “It was revealed during the medical test performed recently at plant premises that most of the employees are having lung-related issues and were referred for further treatments/medications.”

The signatories also referred to arsenic and selenium content in fly ash. They expressed concern about radiation – something which has not been measured at Lakvijaya in recent times. “Fly ash is only part of the problem,” they said. “Coal dust is spread all over the plant due to wind and lack of proper dust suppression mechanisms in the coal yard and conveyor belts/chutes.”

These were serious issues and needed to be addressed as a top priority, they urge. “Most importantly, it is unethical to maintain the plant working conditions at such a damaging level for the lives of both our subordinates and the nearby villagers,” they stress.