Aflatoxins in Coconut oil

View(s): Edible vegetable oils are an important component of the Sri Lankan diet. They are widely used to frying or temper during cooking or used in food processing industries. Coconut oil is the most widely used vegetable oil in Sri Lanka. According to Central Bank statistics 2019, Sri Lanka produced around 44,648 metric tons of coconut oil mainly for domestic consumption.

Edible vegetable oils are an important component of the Sri Lankan diet. They are widely used to frying or temper during cooking or used in food processing industries. Coconut oil is the most widely used vegetable oil in Sri Lanka. According to Central Bank statistics 2019, Sri Lanka produced around 44,648 metric tons of coconut oil mainly for domestic consumption.

The annual requirement of coconut oil for domestic and industrial purposes is about 180,000 metric tons (CDA statistics) and has to be imported to meet the demand. The coconut oil that is imports to Sri Lanka come as crude or unrefined oil due to lower price and import tariff.

What are Aflatoxins?

Aflatoxins are toxic secondary metabolites produced by fungi named Aspergillus flavus, A. parasitics and A. nomius and the most important mycotoxins with regard to the occurrence, toxicity, and impact on human health and trade. These fungi may infect and proliferate on a broad range of agricultural commodities, including copra, peanuts, corn, cottonseeds, sorghum, tree nuts, cocoa beans, spices, and rice resulting in the production of aflatoxins.

Aflatoxins were first discovered in the early 1960s after more than thousands of turkeys in England died of poisoning from mould-contaminated Brazilian groundnut meal.

Fungi or moulds are the main cause for spoilage and deterioration of food and feed crops. The fungi grow readily in tropical and subtropical conditions, with ambient temperature, moisture content and improper post-harvest practices. Fungi can infect crops in many stages; when the crop is in the field, while harvesting, transportation or storage. Cereals, cotton seeds, peanuts and tree nuts are reported to be the most highly infected food products due to improper drying and storage.

Fungi or moulds are the main cause for spoilage and deterioration of food and feed crops. The fungi grow readily in tropical and subtropical conditions, with ambient temperature, moisture content and improper post-harvest practices. Fungi can infect crops in many stages; when the crop is in the field, while harvesting, transportation or storage. Cereals, cotton seeds, peanuts and tree nuts are reported to be the most highly infected food products due to improper drying and storage.

The fungal genus Aspergillus has more than 200 species but it is reported only less than 20 of them produce aflatoxins. Aspergillus flavus and A. parasiticus are two species that produce toxic aflatoxins contaminating a wide range of food and stored grains that affect human health. Aflatoxin is produced at a temperature of 12-40 0C and requires 3-18% moisture. Out of about 20 aflatoxins identified, mainly B1 (AFB1), B2 (AFB2), G1 (AFG1), G2 (AFG2) and M1 (AFM1) are of public health importance. Aspergillus flavus mainly found in soil, corn, cotton seeds and tree nuts produce only B group aflatoxins whereas A. parasiticus in peanuts, produces aflatoxin B and G. Aflatoxin M1 is produced in the liver of animals following ingestion of high levels of aflatoxin B1 through animal feed, and it may be excreted in the milk and urine of animals. By consumption of aflatoxin-contaminated milk and milk-based products, aflatoxins M1 could indirectly enter to the human body. Aflatoxin B1 is reported to be the most potent and abundant toxin and classified as a class 1 carcinogen for humans.

In the process of manufacturing coconut oil, the fresh coconut kernel, which contains a high percentage of water and oil is sun-dried and then subject to hot air curing to produce copra with a moisture content of less than 6%. During the drying process of coconut to get copra and storage, due to less hygienic practices, Aspergillus fungi can grow and produce aflatoxins.

Aflatoxins are difuranocoumarin derivatives with a bifuran group attached to one side of the coumarin nucleus, while a cyclopentanone ring (group B) or δ-lactone ring (group G) is attached to the other side. Aflatoxins are innately fluorescent compounds. They are named due to the colour they emit, AFB1 and AFB2 emit blue fluorescence and AFG1 and AFG2 green fluorescence.

What are the health effects

of aflatoxins?

Humans can be exposed to aflatoxins by consumption of aflatoxin-contaminated foods. It is recorded that inhalation of AFB1 contaminated dust particles may increase the risk of getting lung cancer.

It has been reported that long term consumption of aflatoxins contaminated foods, can cause aflatoxicosis, which is toxic hepatitis leading to jaundice and in severe cases, death. Aflatoxins mainly target the liver and chronic aflatoxicosis causes liver cancer, immune suppression and birth defects by the toxic effect on the embryo or fetus.

Although AFM1 is less carcinogenic, it exhibits high genotoxic activity in both humans and animals.

Prevention and Decontamination of aflatoxins in edible oils

Proper pre-harvest and post-harvest handling are the easiest methods to prevent mould formation in crops, cereals and nuts, which will prevent the formation of aflatoxins.

The toxicity of aflatoxins and their impact on food security, human and animal health led to many studies on decontaminating it from foods. Aflatoxins are highly heat stable and difficult to eliminate by conventional thermal treatments. Several physical (UV and gamma irradiation, microwaving, pulse light, absorbance), biological (using yeast and bacterial cells and enzymes) and chemical (Ozone, Sodium hydroxide, Sodium bisalphate, Hydrogen peroxide) techniques have been used for effective control and management of aflatoxins in foods.

The process of alkali refining of crude vegetable oils with Sodium Hydroxide followed by washing with water and bleaching reduces the aflatoxins levels.

How Aflatoxins are detected?

Once the food commodity is contaminated with aflatoxin or any other contaminant, accurate assessment need to be carried out to detect the level of contamination. There are many methods such as Thin Layer Chromatography (TLC), High Performance Liquid Chromatography (HPLC), Enzyme-linked Immunosorbent Assay (ELISA) and LC-MS-MS used to detect the levels of aflatoxin contamination.

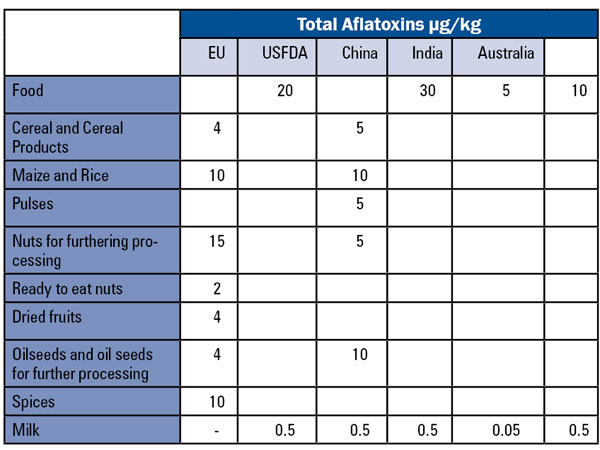

Maximum permissible levels for aflatoxins in food and animal feed has been decided by regulatory bodies of the country.

In 1960, Dr W R N Nathanael from Coconut Research Institute, Lunuwila first reported the contamination of copra with fungi Aspergillus causing considerable loss and depreciation in the yield of coconut oil. Further studies by Prof. S N Arusecularatne, Dr U Samarajeewa and their research teams in 1970s and 1980s and recent study by Nuwan B Karunaratne and the research group, had reported the aflatoxin contamination in coconut products and coconut oil.

Sri Lanka should adhere to limit given by Sri Lanka Standard Institute and according to SLS 32:2017 for Specification for Coconut oil, the product shall not exceed the level 5.0 µg/kg for aflatoxins AFB1 and 10.0 µg/kg for total aflatoxin.

Industrial Technology Institute (ITI) with its experience and qualified scientists and high-end instruments are always ready to assist with any national issues. ITI has been engaged in aflatoxin testing in the different matrix such as spices, cereals, tea, milk, coconut oil etc. using TLC and HPLC for many years. Currently, the tests for aflatoxins are carried out using the LC-MS-MS producing more accurate and consistent results and enabling much lower aflatoxin detection limits. ITI issues many test reports monthly, on aflatoxins in chillies, curry powder, masala powder, cereals, ayurveda preparations, food and oils on the requests from the respective industries.