Shifting gears

View(s): Shaveen Jeewandara speaks to young students at the Moratuwa University who’ve converted an old mini into an electric vehicle

Shaveen Jeewandara speaks to young students at the Moratuwa University who’ve converted an old mini into an electric vehicle

The rattling blue 1967 Mini Cooper -aptly named ‘Nilmini’ by the staff and students of the University of Moratuwa- used to bumble down its streets with the university’s first vice-chancellor Dr. L. H. Sumandasa at its wheel. Being privy to every nook and cranny of the university, Dr. Sumanadasa felt it was right to donate his prized car to the Motor Lab of the Mechanical Department upon his retirement in 1975. But it wasn’t glory days that followed for Nilmini, as she grimly sat in the lab for over four decades.

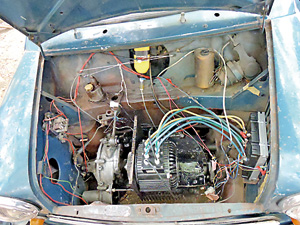

Now she’s back. Trading her engine and fuel tank for a motor and battery in keeping up with the times. “Meet Nilmini,” smiles Mechanical Engineering lecturer at the University of Moratuwa, Sasiranga De Silva as he points at the car which is ofcourse.. blue.

Having resuscitated the old car, the team comprising of supervisor Sasiranga, Vimukthi Randeny – now an engineer, DIMO automobile training school, Anuradha Herath , Instructor, Department of Mechanical Engineering and Chathura Ganeemulla, Mechanical Engineer, Industrial Solutions Lanka, have effectively converted it into an electric automobile that can hit a top speed of 77 kmph.

Working on the mini as their final year project, the team had faced challenges thrown at them by the unique architecture of the mini. “This wasn’t merely about pulling the engine out and replacing it with a motor,” says Vimukthi, the face behind the idea. “We had to create the motor in such a way that it would not interfere with the original structure of the car.”

Working on the mini as their final year project, the team had faced challenges thrown at them by the unique architecture of the mini. “This wasn’t merely about pulling the engine out and replacing it with a motor,” says Vimukthi, the face behind the idea. “We had to create the motor in such a way that it would not interfere with the original structure of the car.”

Explaining the technicalities of the challenge, Sasiranga tells us that the engine and gearbox of the mini is in-fact one unit, and thus they had to create a motor that would fit right in without hindering the gear-box. “This is where engineering kicks in, and you’d be surprised to know that the current system is held in place by only twelve bolts,” says Vimukthi.

We learn that the coupling of the motor to the gearbox involved manufacturing three gear wheels and a final drive shaft; all of which were manufactured in the university. “There’s vast potential amongst us to do such things but the only shortcoming is funding,” they resound.

Driving the electric mini is easy and is quite a pleasure as it accelerates and handles even better than the standard mini. “Much of this is due to the greater torque (force acting on an object that causes it to rotate),” says Sasiranga. The four cylinder, 850 cc mini delivers only 35 horsepower but it generates considerable torque. “Horsepower sells cars, but torque wins you races,” chips in Vimukthi.

Having planned meticulously for over six months, the team took only two months for the final conversion which replaced the traditional fuel tank for six 90 ampere lead-acid batteries, making sure that Nilimini left no carbon footprints as she began running again.

Having planned meticulously for over six months, the team took only two months for the final conversion which replaced the traditional fuel tank for six 90 ampere lead-acid batteries, making sure that Nilimini left no carbon footprints as she began running again.

The mini car ran for approximately 40km with one round of charging, but the team believes that their next modification will bring about serious changes in mileage. “The next step is to connect the battery to a super capacitor,” they tell us. As the name suggests, a super capacitor is an electrical component that stores large amounts of electrical energy and will complement the battery in providing a backup source of energy in scenarios where more power is needed.

“One of the major concerns of electric vehicles is the major strain applied on the battery, by using the super capacitor we can minimize this strain and effectively elongate the battery-life,” says Vimukthi.

“It’s important to change the ideals of people and their conception of electric vehicles,” says Anuradha. “Although people are alarmed that an electric vehicle can only run 100 kilometres with one charge, they do most of their driving within the city. To and from work mostly.”

“If the government fixed charging points around the country and also gave a concession on electricity bills for electric vehicles, we will see a vast increase in the number of electric vehicles on roads,” adds Anuradha. Ultimately creating an emission free environment, innovations such as the ones made by the team at University of Moratuwa will drive the electric automobile industry forward.

The next step for Nilmini? “A plug in charging system,” Vimukthi reveals with pride. While the conversion of the old mini into an electric vehicle is a feat in itself, the team is determined to take their engineering skills to the next level by fitting in a plug-in charging system for the car. Nilmini bustles back into the garage after a few laps around the university, bustling with pride knowing that she’s got a lot more in store in the future.

The Magazine cover

features the young

students from

left to right Anuradha,

Vimukthi and Sasiranga.