News

3D Printing comes alive at the NHSL

In the midst of the hustle and bustle of the premier hospital complex that is the National Hospital of Sri Lanka (NHSL), a revolution of a different kind is taking place.

All products of 3D Printing

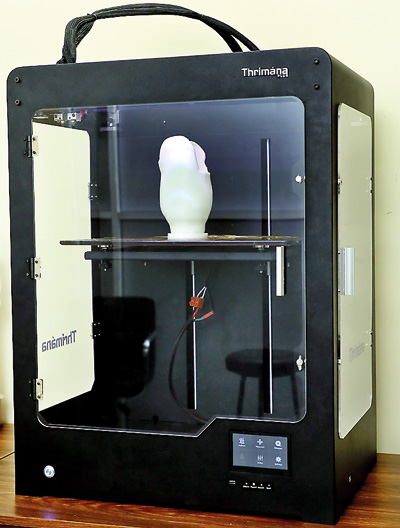

Deep within the Orthopaedic Building in the Orthopaedic Workshop, a simple black steel and glass box takes pride of place.

The 4th Industrial Revolution has come with major force to the state health sector and is probably a first in the medical arena in the country.

It has brought succour to humble patients from all over the country awaiting prosthetics who now have access to the cutting-edge technology of 3D Printing.

Before we see this marvel-machine at work in the 3D Printing Studio, customizing each and every limb for those in need, the Sunday Times gets an overview of what 3D Printing is all about from NHSL’s Deputy Director Dr. Samiddhi Samarakoon who is in charge of the hospital’s Accident & Orthopaedic Service.

Giving a simple explanation of a complex subject, she says that ‘3D Printing’ or ‘Additive Manufacturing’ is theprocess used to synthesize a three-dimensional object in which successive layers of material are formed under computer control to create an object. (Synthesis is the combination of components or elements to form a connected whole.)

It means that the 3D Printing process builds a 3-dimensional object from a computer-aided design, the Sunday Times understands.

Awaiting a supportive device is 32-year-old Tharaka Madhushan from Wellawaya.

Riding his motorcycle to work in the afternoon, Madhushan into IT work, had been involved in a major accident in August last year.

“I had fallen asleep and crashed into a lamp-post,” he says, showing his scarred left leg. Now having undergone many procedures and grafting, he is awaiting a supportive device to straighten his foot.

“Can you see it’s bent? The muscle has contracted and a supportive device will help to prevent further contraction and aid in contraction-reduction,” explains a health worker.

Dr. Samiddhi Samarakoon

Looking around the region, meanwhile, Dr. Samarakoon says that though 3D Printing is not new to the world, having been there for around 30 years, it was only last year (2018) that a 3D Printing facility to manufacture artificial limbs was established at the Department of Orthopaedics of the Kasturba Hospital in Manipal, India.

This is while it was just this year that Malaysia set up a 3D Printing Centre of Excellence in a hospital for their research teams to develop 3D Printing applications for the marketplace.

South Korea’s Severance Hospital in Seoul, meanwhile, is preparing to commercialize 3D Printed prosthetic eyes, as around 60,000 patients in that country require artificial eyes, but only 40,000 have access to them.

She cites another example – how new hope has been given to Yemeni war victims by a hospital in Jordan by providing 3-D printed prosthetics this year.

Detailing why 3D Printing technology has been introduced at the NHSL, Dr. Samarakoon points out that it would reduce the labour-intensive process in the manufacture of prosthetics and orthotics, while being cost-effective and more accurate. An added advantage would be that technicians armed with the portable scanning machine could go to the homes of patients who are unable to come to hospital.

“We can also set up a digital library with patient records,” she says.

However, a few challenges such as improving the 3D designing skills and IT literacy of workers; optimizing the development process; and finding suitable material for different cases would need to be overcome, it is learnt.

The 3D Printing machine

With the NHSL as an active hub in 3-D Printing, the authorities are hoping to seek support from specialists in both the government and private sectors to improve the manufacturing process, while expanding this facility to other fields such as dental, ear-nose-and-throat (ENT), neuro-trauma etc.

Examples where this technology will come in handy are numerous. Ill-fitting hearing-aids a common complaint would become just a memory with this technology, while for those with a smashed or severely damaged skull, the imaging through this technology would be invaluable as neurosurgeons can plan the surgery with precision.

Dr. Samarakoon talks of a recent request with regard to a patient suffering from cancer in the mandible (lower jawbone) – the scanning would help demarcate the eroded sections accurately.

The sights are set to introduce metal, ceramic, wax and bio printing technologies to the health sector and also manufacture the implants in-house using 3D Printing technology.

The use of 3D Printing in dental applications is widespread, she says, pointing out that in the United States of America, one laboratory alone manufactures around 1,000 crowns and anatomical top units. Porcelain is fused to metal crowns to give that natural look, she smiles.

For this benchmark achievement in the state healthcare system, she appreciates the invaluable support extended by Health Minister Dr. Rajitha Senaratne; the Director-General of Health Services, Dr. Anil Jasinghe; the Director of Health Information Dr. A.I. Jagoda; and the Director of the NHSL, Dr. Kumara Wickremasinghe.

The future opens up for Sri Lanka…..with visions of major organs such as kidneys, livers and hearts also being 3D Printed for those in dire need.

Health Minister Dr. Rajitha Senaratne examines a limb produced through 3D technology at the inauguration of the programme in September. Looking on (on the left) is the Director-General of Health Services, Dr. Anil Jasinghe. Pix by M.A. Pushpa Kumara

| The present and the past | |

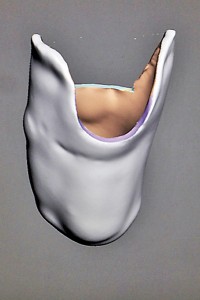

With the 3D Printing Solution being available in the state medical service, the creation of prosthetics (artificial body parts such as limbs) or orthotics (artificial devices such as splints or braces as well as supports for those with diabetic foot) has become smoother.  Tharaka Madhushan awaiting a supportive device The step-by-step 3D Printing Solution which we see in operation at the Orthopaedic Workshop involves:

Usually what happens when manually crafting a prosthetic is that measurements are taken, followed by a mould being made and rectification through the manufacturing of the outer layer and the inner sheet carried out. Then the kit is assembled and the initial fit-on is carried out, after which the lower part of the limb is created, followed by the final fit-on. However, there are several challenges on the way, including measuring errors or the blue-print getting damaged or destroyed, leading to the product not meeting expectations, while the whole process is labour-intensive. “The potential and opportunities in 3D Printing are immense,” says Dr. Samiddhi Samarakoon referring to the designing of customized medical devices; how there can be meticulous surgical planning and equipment modifications; how bio-engineering can be integrated into this field to manufacture advanced limbs; how Sri Lanka can become a resource hub for medical research; how it enables researchers to produce medical education models; and how other hospitals across the country can seek support from the NHSL. Currently, the NHSL is using plastic printing but hopes to move to metal, titanium and even bio-cell printing in the future, says the Deputy Director, adding that in artificial limb printing at the moment the focus is on printing alone. “We have plans to bring in the bio-engineering aspect to add neuro-sensors.” Plans are aplenty, with Dr. Samarakoon initiating discussions with the Dean of the Colombo Medical Faculty, Prof. Jennifer Perera, on the potential of her staff sharing their innovative ideas with the NHSL. “This technology can turn ideas into practical solutions,” adds Dr. Samarakoon.  Pic 1  Pic 2  Pic3  Pic 4  Pic 5

|