University of Moratuwa’s MechX-2019 showcases local talent

WIND-BLOWN IN MORATUWA: Not only did Dinusha Silva have to reach into his pocket to fund his final year project for the annual exhibition to showcase the talents of undergraduates emerging from the Department of Mechanical Engineering at the University of Moratuwa, but he also had to suffer an injury in the pursuit of his venture.

Small-scale wind turbine with its inventors - P.R.M Adikari, B.M.I.R Bandara and M.D.I.C Silva. Pix by Ishanka Sunimal

The plan of his team, also comprising Roshan Adikari and Isuru Bandara, was to design and develop a small-scale wind turbine suitable for use in Sri Lanka. With wind being the third most renewable energy source in Sri Lanka, the Government has plans to get 45 per cent of its renewable energy from this source by 2050.

While wind farms are already up-and-running in the island, the three undergraduates, all hailing from Gampaha, discovered the cost of producing energy was high and that some turbines are not performing as expected. So they carried out a study to develop a better turbine model feasible in the Sri Lankan context – mainly one which could operate in low wind conditions.

“The cost of producing power we discovered from the current turbines in use is around 40 rupees per unit. Our model can reduce this cost to 26 rupees per unit,” says Adikari proudly.

Standing by is Silva, sporting an ugly band-aid on his head. What happened, I ask? “While testing our model, one of the blades broke free and hit me on the head,” smiled Silva.

The trio had been testing their experimental turbine on the Piliyandala-Kesbewa road. The model had been strapped outside to an open vehicle and driven at speed to generate wind-speed. One of the blades broke free and Silva was in the way. Luckily the turbine hadn’t reached optimum speed of 700 revolutions per minute. If it had, he would have needed more than one stitch to staunch his head injury.

Need financial support

Talk about the person who falls from the tree being gored by the bull, pithy when said in Sinhala. Silva not only had to pay to complete his project, and his instant reward was a blow to his head.

Another product on display

The 120 undergraduates in this final year of Mechanical Engineering at Moratuwa University had each been given Rs.25,000 towards their project. Hardly enough, and all of them have had to find more money and even depend on the lecturers’ generosity to complete their projects which comes at the end of their degree programme.

The dream is to catch the eye of local or foreign companies with an idea novel enough to be turned into a profitable commercial venture. MechX-2019, held on Monday and Tuesday this week at the university, did attract considerable interest from the private sector as 33 projects were showcased in the areas of: Energy, Manufacturing, Mechatronics, Automation, Robotics, Automobile, Aeronautics, Biomedical and Industrial Engineering.

“We hope hotels along the coast of Sri Lanka will be interested in investing in our wind turbine. They can showcase their hotels as using renewable energy and being eco-friendly and I’m sure that will be a huge draw for tourists,” Adikari dreams.

The rough cost of building a wind turbine which will generate 3,800 kilowatt hours per year is around Rs.1 million, according to Adikari and his team. They can scale up according to needs.

The government’s Sustainable Energy Authority had been initially interested and Adikari and company have plans to keep pursuing this avenue too.

Among the gawking undergraduates is Chethika Samarakoon. She stands out from the crowd in her stiletto heels and smartly tailored pants. But the attraction is just more than cursory, for she holds the power in her hands to offer some of these undergraduates an opening for a better future.

Scouting for talent

Chethika is Assistant Human Resources Business Partner for Supply Chain at Unilevers. Last year one of her selections from the university is now a management trainee at the global multinational.

“There is a lot of talent at Moratuwa University and we are looking for people who will be a natural fit with Unilevers. We don’t just take final-year graduates but we get involved early by identifying potential talent from the second year on,” says Chethika.

Ruwan Gopura, Head Professor of Mechanical Engineering, Department of Mechanical Engineering at the University of Moratuwa, is thankful for the interest shown by Unilever and the presence of the scouting Chethika.

Chethika Samarakoon

“In Japan, after a student completes his or her degree, they are all given two years of industrial experience as trainees by big companies like Toyota. Unfortunately, in Sri Lanka we lack these opportunities. We have a lot of talented young minds but most of them struggle to find a good job,” reveals Prof. Gopura.

On the same floor of the exhibition are Rashane Perera, Samith Hettiarachchi and Gihan Pathirana, another team who have designed an automated fluid management system for endoscopy aided gynecological surgeries.

“We have developed a system where a sensor can calculate the saline level inside the body when an operation is being done. In the current method, there is a risk of fluid overload occurring with the absorption of saline by the body tissues which may result in complications and even death as occurred a few years ago,” explains Rashane.

His team has designed a system where the saline levels can not only be measured accurately but one which also controls the flow rate. This system can be used for many operations; the current machines used in many hospitals can only be used twice as the flow rate is fixed.

“Ours is very cost-effective and it will help doctors in their operations as they won’t have to worry about keeping an eye on the saline levels as everything is automated with a sensor to show when levels reach dangerous highs,” adds Rashane.

A hysteromat – a machine used for these operations – on the market costs around Rs.2 million. Rashane says the Moratuwa product will cost under Rs. 500,000. I didn’t see any doctors queuing up to talk to Rashane and company. Perhaps the GMOA was busy planning their next strike.

Load-lifting robot

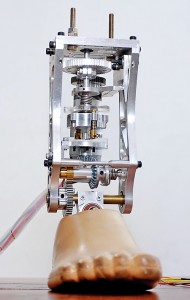

For companies who employ people in repetitive jobs and in production lines, then the hip exoskeleton robot developed for load lifting by Vinura Mannapperuma, Shehara Perera and Pasindu Hettiarachchi is a must.

The exoskeleton robot is a wearable device that works in tandem with the user replicating human movements like lifting a weight. It provides support and reduces muscle fatigue.

New invention

“We have found out that in most companies where load-lifting is required, the person can work one day but the next day he can’t continue. In Britain, more than 50 per cent of disorders in the workplace comes from lifting. Companies have to pay for insurance and healthcare and also employ more workers. Our system can provide an extra 30 per cent support and help the worker,” reveals Vinura.

And it comes relatively cheap – the cost for one of these systems is around Rs.350,000. Perhaps a far better investment than paying for medical care and lost man-hours.

Senior lecturer Pubudu Ranaweera who along with Prof. Gopura supervised this project, rues the fact that money for research and development is scarce, not only at Moratuwa University but in most other universities around the island.

“The Government is willing to give us some more money provided we increase our annual intake of graduates. We take in 120 students every year for Mechanical Engineering. But the facilities we have were originally made to cater for 60 students. We have no new workshops or laboratories.

How can we increase our intake,” asks Ranaweera.

Despite the limited facilities, the university is doing its best. But at the end of the day, Sri Lanka loses some of its best talent overseas to the brain drain.

“If this country is to develop faster, we need our best brains to lead. What is happening now is the best people go overseas to continue their studies or for jobs while those who remain are those with lesser skills. These people end in leadership positions which results in a lower rate of development in the country,” bemoaned Ranaweera.