![]()

The

past few months have seen the closure of over 100 rice mills in the Polonnaruwa

District.

The

past few months have seen the closure of over 100 rice mills in the Polonnaruwa

District.

Sri Lanka, once known as the Granary of the East seems to have forgotten

its agrarian roots of yore. The efforts of ancient rulers to cultivate

the land expanse of this country have come to a halt-replaced by trends

which drive the few remaining  cultivators

to poverty and despair. In this instance, it is the miller on the brink

of disaster.

cultivators

to poverty and despair. In this instance, it is the miller on the brink

of disaster.

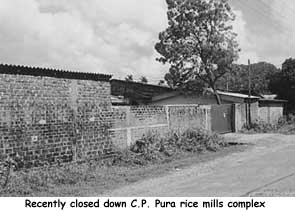

As we drove through historic Polonnaruwa, we saw the recently closed down milling complex named C.P. Pura in honour of former Minister C.P.de Silva and the kamathas (threshing field) fallen to disuse, now housing cattle.

Farmers by practice, do not sell large stocks of paddy at once. Instead, they resort to selling small paddy stocks which the shop keepers store. It is from these middlemen that millers have to buy paddy.

Though paddy is purchased at the certified price of Rs.7.42 per kilogram,

the rice prices are heavily influenced by the  fluctuating

fortunes of the Pettah market. As there is no price control, the rice prices

are determined by the Pettah dealers depending on the prevalent supply

and demand trends. It is the same dealers who import rice.

fluctuating

fortunes of the Pettah market. As there is no price control, the rice prices

are determined by the Pettah dealers depending on the prevalent supply

and demand trends. It is the same dealers who import rice.

Several decades ago, only government authorized millers operated in the country. On a smaller scale, mills have operated as a cottage industry in most parts of Raja Rata. Subsequently, the small mills were granted industrial status. Despite the increasing number of mills in the country, rice production is still minimal owing to the lack of modern technology and the high cost of labour.

According to statistics, other countries produce 70-75 kg of rice out of 100 kg of paddy, but here the maximum rice production is around 60 kg.

Polonnaruwa District Parliamentarian Rukman Senanayake told The Sunday Times the root of the crisis was the lack of a balancing act to save both the paddy cultivator and the rice miller. For the first time in recent history, there has been a shortage of about 9,9 mammoties which are exclusively used for cultivation purposes. Though the last one and a half years saw an intensive drive by the government to promote cultivation, with seven continuous seasons being undertaken, these difficulties hampered production.

When paddy prices shot up last year, every possible inch in Polonnaruwa was cultivated by the eager farmers. They resorted to heavy borrowing and obtaining bank loans. The enthusiasm was such that even government reservations were cultivated. The prices dropped shortly, causing farmer's dreams to go bust.

According to millers, bankruptcy went hand in hand with milling. In every other industry, prices were determined by the producer except in this one.

Our mills mainly produce two varieties of rice, the raw and polished with the variety known as "Nadu" having the highest consumption. In order to keep afloat during lean periods, each mill retains a small security stock. During nonproducing periods , it is these stocks which are pounded..

The process of producing rice is time consuming due to outmoded milling methods, as we witnessed at the Beliatta Rice Mill, Giritale. The mill provides direct employment to 30 people.

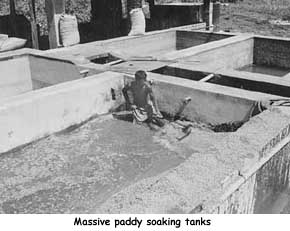

Each mill has about four soaking tanks which are used to soak paddy.

The seedless paddy crusts start floating and are  removed.

Thereafter paddy is transferred to the retaining tanks.

removed.

Thereafter paddy is transferred to the retaining tanks.

The paddy is then transferred to conical paddy boilers. As there are no electronic dryers, paddy is allowed to dry in the air. Then the crust is peeled off and put to the combination huller. This machine produces the grade 1 rice, the once destoned and twice destoned rice. The husk is removed by the fan, and rice is stored and packeted.

The normal assessment is that a rice mill requires a Rs.3-4 million

working capital. Outmoded Chinese destoners which are not 100% fool-proof

are still in use. Modern machinery requires an over 1 million rupee investment,

unaffordable to the regular  miller.

miller.

P.Sumanaratne is the owner of the Sarojini Rice Mill which was closed last year.Having invested everything in the mill, he finally sold his Colombo residence to pay off debts.

"Just as my small mill was gaining ground, the government began importing rice. I have raised a loan through a mortgage and incurred heavy losses unable to sell rice. I have now resorted to buying paddy waste to make animal foods."

Situated in front of the now closed C.P.Pura Milling Complex in Katukeliyawa lies the Kumudini Rice Mill owned by Athula Akuretiya. Symbolic of the previous statement, there was a massive pile of stone and other paddy impurities in his compound.

Apart from the travails of milling, he has the extra disadvantage of being a target of elephants who love to drink paddy soaked water.

"The biggest problem the millers faced was the relaxing of the

35% import duty on rice. With the reimposition, there was a glimmer of

a hope. People believe that this is a big business, but in actual fact

we only remove the husk. Therefore it is unfair to  categorize

us as a manufacturing industry, making us pay income tax, other duties,

BTT and 4% defence levy" he lamented.

categorize

us as a manufacturing industry, making us pay income tax, other duties,

BTT and 4% defence levy" he lamented.

Further arguing why the levies were unfair and burdensome, he said that a kg of rice cost Rs. 24. It was the miller who packeted rice , bore the electricity, transport and labour charges which certainly exceeded his production cost.

Akuretiya believes that more incentives like removal of taxes and loan interest would help them tremendously. BOI status for two years until the business gets off ground was another request.

Wahab who runs the Parakrama Rice Mill in Giritale is contemplating closure. His debts have increased so much due to high cost of production, he says.

Despite the certified price of paddy being Rs. 7.42, we purchase paddy at Rs. 10. One pack of rice containing 65 kg of rice is normally purchased at Rs. 650. Though purchased at high cost, there is no way to recover the resultant high production cost. Rice price is incredibly dependent on the prevailing paddy prices.

"It is not the big importer who has to suffer, but the small fry.

With the imported rice flooding the country, the rice produced at great

cost and suffering cannot be marketed. Once marketed, the shops can reject

our rice at will, and their payments are irregular. Paddy cultivators at

least have the Paddy Marketing Board to rely on, but we have none to ease

our load by way of  a

guaranteed purchasing centre."

a

guaranteed purchasing centre."

P.R.B. Dahanayake's fortunes went downhill recently, and he had to sell some of his assets to retain his Jayasiri Rice mill.

His biggest grouse was that there was no mechanism available to remove the black stones at an affordable price, resulting in inferior quality rice. With the millers facing a crisis situation, the daily production of rice has plummeted from 150 rice tons to a mere 20 tons per week.

"How can the government wash its hands off this responsibility? It should be part of the agricultural policy to protect the farmer. If the farmer is protected, the benefits would naturally spill over to the milling industry. Instead, they add to the wealth of middlemen who buy paddy stocks from farmers. All this results in a low output," he added.

A.C.S. Hameed is the manager of Asha Rice Mill at Raja Ela, Minneriya. Hameed was mostly discontented for two reasons- Tamil labourers often being taken into custody by the Police and non-millers retaining small stocks of rice which they undersell to build a clientele.

"Professionals in other fields should not do this for it sends

us off business. At this rate, only massive businessmen with large  mills

would remain in the industry. The state considers us as manufacturers,

but this is wrong for we are fighting for survival."

mills

would remain in the industry. The state considers us as manufacturers,

but this is wrong for we are fighting for survival."

Sunil de Silva, President of the Rice Millers Association and owner of Beliatta Rice Mills counts 25 years in the rice milling industry. The mill was inherited by Sunil two decades ago.

It is his contention that milling is one industry for which there are no incentives provided by anyone with millers having no profit margin.

Calling for a comprehensive government policy on the agriculture and rice production, he is of the view that the government must formulate a rice purchasing scheme during flush periods at a certified price and retain these as buffer stocks. This would also render the exercise of importing rice unnecessary.

"No country has allowed a private sector monopoly of rice production overlooking the local producer. Here is a situation of not having any safeguards for us. Even though most capitalist counties such as America have taken measures to protect the local industry, Japan even has rice control laws. There, the import and export of rice, adjustment of prices, prevention of quality control and marketing are government controlled."

'It is an industry, despite the people's belief of its being a profit making one, which does not even receive crumbs. While introducing a certified price, compelled to import, it also must ensure purchasing part of local production. The reimposition of the 35 % import duty on rice was a step in the right direction,"he added.

It is indeed sad that the country's staple food producers are given step motherly treatment. Little has been done to secure this industry and stabilize the economy. When bread was given a subsidy of Rs. 1.50, the benefit flowed to the unknown American wheat farmer and not to our own.

The millers have many proposals to improve their industry, such as imposing the standards recommended by the Sri Lanka Standards Bureau, the relaxing of many levies including the defence levy, BOI concessions for at least two years, duty free concessions to modernise mills and a government institution to purchase and distribute rice during times of shortage.

Continue to Plus page 6 * Beat the heat at Oasis

Return to the Plus contents page

![]()

| HOME PAGE | FRONT PAGE | EDITORIAL/OPINION | NEWS / COMMENT | BUSINESS

Please send your comments and suggestions on this web site to

info@suntimes.is.lk or to

webmaster@infolabs.is.lk