Water footprints: A guide to efficient water use in plantations

The world economic forum in 2016 has ranked the water crisis as the highest concern over the next decade. We in Sri Lanka are beginning to sense this crisis and the uncertainties in weather patterns further aggravate this issue. Different parts of the country experience shortages of water for day-to-day activities including drinking and for agriculture whilst the entire country is affected economically and environmentally by depleting levels of capacity to generate hydroelectric power.

File picture of a woman transporting water on her bicycle.

It’s a global concern and this has led the entire world to be more vigilant about water use. So much so that various tools are being developed to estimate the water consumed to manufacture different products and also to provide different services to mankind.

Water footprint

One such tool or a methodology is the calculation of the water footprint. Water footprint refers to the amount of water used to produce different products or provide different type of services to human beings. For example the amount of water used to produce a shoe or a shirt is the water footprint of that particular article. It can be estimated for a product, a service, an individual, a country and even the whole world. An individual’s consumption of fresh water based on the products and services he or she uses or consumes per year is that person’s water footprint.

We use a lot of water in ways that we would never anticipate often referred to as hidden water in everyday products, such as in the production of clothing, i.e., the production of one cotton suit might require over 14,000 litres of water and almost 3,700 litres for a cotton shirt. The water required for manufacturing a cell phone may be as much as 916 litres. This includes the water necessary to make the raw materials/components of the product, the water needs of the human resources used during the manufacturing process and also water required to treat waste generated during the production process.

An individual may not drink, feel or see all the water he or she uses or consumes. This is called, “Virtual Water” and it actually makes up most of our water footprint. The combined total of direct and indirect usage of water in the lifecycle of products and related services all play a role in the overall footprint calculation. Knowledge on the water footprint of a particular product or a service would enable us to make processes more efficient so that we could control the use of this valuable and limited resource.

There are three different types of water footprint namely Green, Blue and Grey. Green water footprint refers to the amount of soil water, which is recharged by rainwater, required to produce a product. It is mainly relevant for forestry, horticultural and agricultural products. Blue water footprint refers to the amount of groundwater or surface water required to produce a product. Domestic water use, industry and irrigated agriculture can each have a blue water footprint component. The amount of freshwater required for incorporating and diluting the pollutants/waste water to meet a particular water quality standard as required by environmental regulatory institutions, e.g., Central Environmental Authority, is the Grey water footprint.

Plantation crops

The plantation industry of our country is more than 150 years old and the land extent utilised at present is around 1,000,000 hectares when crops found in home gardens are also taken into account. The families dependent on the industry both directly and indirectly is not well documented but could easily exceed a million. Since the water is a basic need in cultivation, processing, manufacturing and waste management the water footprint of the plantation industry has been a significant aspect in making decisions on the plantation economy. Accordingly, the water footprint for different commodities and products of plantation crops has been calculated worldwide and well documented. This information could be of immense value to all stakeholders of the plantation industry today, since there is a debate on which crop consumes more water and hence whether such crops are suitable to be included into the crop mix of the plantation industry in a country. The concept of water footprint therefore provides more scientifically valid information for policy makers to take environmentally sound decisions on the development projects of the plantation industry which is still a vital industry in the Sri Lankan economy. Also, such information is of much use for each and every responsible citizen and organization of the country that supports the development of the plantation sector to decide on sustainable development projects and to maximise community engagement in such projects through creating awareness with correct facts.

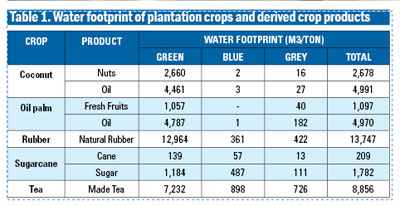

Mekonnem and Hoekstra attached to the University of Twente, The Netherlands have published water footprint of crops and derived crop products in 2011 (www.hydrol-earth-syst-sci.net/15/1577/2011/doi:10.5194/hess-15-1577-2011). Their study has quantified the water footprint of global crop production in a spatially explicit way for the period 1996 to 2005. Therefore, the findings of this study is valid to compare the water use of different plantation crops like coconut, oil palm, rubber, sugarcane and tea that are being widely grown in Sri Lanka. As per this study for each of these crops the green, blue, grey and the total water footprint values are given in Table 1.

The green water component is the water received from precipitation that is stored in the root zone of the soil and evaporated, transpired or incorporated by the plants. When it is expressed in terms of cubic metres required for producing one metric ton of the crop produce, water use efficiency of the crop (i.e crop productivity per unit of water used) is also factored into it. Accordingly, among the different plantation crop produce, the green water component is lowest in Sugarcane and is followed by Coconut, Oil palm, Tea and Rubber. Hence the green water usage of 1,184 m3 tons for sugarcane is the lowest and this could be attributed to the fact that plant species having the C4 mechanism of photosynthesis for which the sugarcane belongs is much more efficient in water use than the plants with C3 mechanism of photosynthesis. All other crop species given in the table above are C3 plants which are less efficient in water usage compared to the C4 plants. Amongst the crops being discussed in this report the highest Green water footprint, i.e. soil water recharged by rain water, was shown by the natural rubber which is around 12,964 m3/ton. This is almost 300 per cent higher when compared with crops like coconut and oil palm.

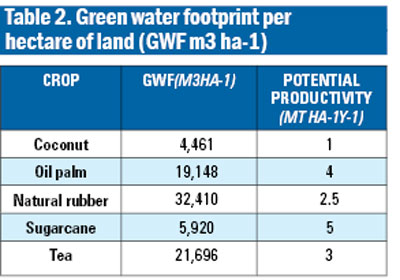

We also calculated the water foot prints in a hectare of land using the potential land productivity (Table 2). According to this analysis the green water footprint per hectare of land per annum is 32,410 and 19,148 of m3 for rubber and oil palm plantations respectively (Table 2). It appears that per unit land the Green water footprint is 170 per cent higher in natural rubber when compared with oil palm.

The Blue water requirement which describes either the ground or surface water used for production and processing of one metric ton of crop produce is highest in tea followed by sugarcane and rubber (Table 1). Respective figures are 898,487 and 361 m3 /ton. The requirement of either ground or surface water for processing is relatively low in coconut and palm oil.

The usage of fresh water to treat both solid waste and waste water generated during processing, i.e. Grey water, is 726 cubic metres for tea, which is the highest amongst the crops discussed in this article (Table 1). It is 422, 111, 40 and 27 cubic metres per metric ton for rubber, sugarcane, oil palm and coconut respectively. The higher grey water usage in the tea industry would include instant tea manufacture as well.

Accordingly, the total water footprint for producing one metric ton each of coconut oil, palm oil, natural rubber, sugar and made tea is 4,991, 4,970, 13,747, 1,782 and 8,856 cubic metres respectively. Among the crops given above producing and processing of natural rubber consumes relatively large amount of ground and surface water when compared with other plantation crops.

Rubber has a higher water footprint

The green water or rain water use of a plantation crop would depend on its genetic makeup and the energy content of the produce. The C4 crop, sugarcane consumes less green water because it is photosynthetically much more efficient than the other crop species mentioned in this article. Crops with a relatively higher percentage of its total biomass in the economic yield, i.e. a higher harvest index, would also lower the green water footprint. However, if the energy value of the crop produce is high that will lead to a higher green water footprint. The energy value of natural rubber and palm oil is around 11,000 and 2,900 kcal kg-1 (https://books.google.lk/books?isbn=1849736316). This coupled with high land productivity, i.e. 4 mt/ha/year of palm oil against 2.5 mt/ha/year of natural rubber would scientifically explain why the green water component is relatively high in natural rubber than in palm oil. When taking the above facts into consideration, it is apparent that in the natural rubber the total water footprint is significantly higher than in the other oil producing plantation crops. Since the study of Mekonnem and Hoekstra represents the global position, one cannot expect the Sri Lankan situation to be so different as to reduce the huge gap in the water footprint of the local rubber and the oil palm industries.

Relative crop water use

The Government of Sri Lanka has taken a policy decision to plant 20,000 ha of oil palm as an import substitution strategy. If well managed this extent has the potential to produce 80,000 MT of palm oil annually. With a total water footprint of 4,970 cubic meters per metric ton the total water footprint for 80,000 MT will be 397.6 million cubic metres of water annually. A similar extent of natural rubber plantations has the potential to produce 50,000 MT of raw rubber. With a total water footprint of 13,747 cubic meters per metric ton of natural rubber the total water footprint for 50,000 MT will be 687.4 million cubic metres of water. Hence for similar land extents, the total water footprint is 173 per cent higher in rubber when compared to oil palm.

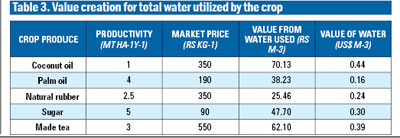

When the value of the primary products of the crops per cubic metre of water consumed is analysed it is significantly high for crops like coconut and tea. This means in those cultivations a unit of water can earn more economic returns to the industry. For example the value creation per cubic metre of water is Rs. 70.13 (US$0.44) and Rs. 62.10 ($0.39) for coconut and tea respectively (Table 3). For sugarcane, oil palm and rubber it is Rs. 47.70 ($0.30), Rs. 38.23 ($0.24) and Rs. 25.46 ($0.16) respectively. In this estimation the net sale averages of primary products of the different crops were taken as per the current trading conditions (Table 3). Also, this information highlights that return to investment of water in the plantation sector is generally low and is an important issue to be addressed by both policy makers and cultivators.

Way forward

The inference from what we gathered above should obviously not be to discourage replanting and new planting of natural rubber in our country based on its high use of green water or rain water usage and the relatively low value creation for the water utilised by the crop. The expanding rubber manufacturing industry in the country requires more raw rubber production in the future. This is also true for other major plantation crops which have now become a part and parcel of our economy and social life. In essence we should not be narrow minded to judge which crop to be planted by considering only one criteria out of a multitude of factors or by prejudice based on occupational affiliations.

The stakeholders of the entire plantation industry should make a concerted effort to adopt a more scientific approach towards the use of an invaluable natural resource like water more effectively and efficiently. Research and development can play a key role. Crop improvement for water use efficiency is one long term approach. Genetic engineering to incorporate the gene responsible for the C4 photosynthetic pathway to all plantation crops would be the best ultimate solution though the progress of global research and development in this aspect is still slow. If such genetically modified plantation crops are cultivated in areas having favourable environments for them, e.g., the intermediate zone of the country, the crop water use will be less with no decline in production. In the short term we need to adopt new and correct technologies in the management of plantations and in manufacturing industries. The green water component required by the plantation crops could be made available without creating shortages for other uses by giving more emphasis for soil and moisture conservation practices so that the rainwater is retained in the soil of plantations rather than surface flowing to end up in the sea leaving us with heavily eroded soil. Further, this initiative would significantly improve the water use efficiency in all plantation crops. The blue water component or the water used during processing of crop produce could be minimised with recycling of water and with new technological developments. The required emphasis is yet to be given to this aspect.

(The authors are from the Faculty of Agriculture & Plantation Management, Wayamba University of Sri Lanka; and the Soil Science Department, Faculty of Agriculture, University of Peradeniya)