Sunday,

April 01, 2007

Vol.

41 - No 44

Tappers to be renamed – Latex Exploitation OfficersRubber: Bouncing back from the brinkBy Antony Motha

Mawanella, nestling in the foothills near Kandy: A group of about 75 men and women stand around a vacant pit. With the exception of one man who is preaching with passion, the group is quiet, their eyes focused on the object being lowered into the two foot square pit. These people brave the midday sun and listen in rapt attention to the sermon being delivered by the missionary. The scene could easily be misconstrued as one of death and burial.But reality is quite the opposite. What is taking place here symbolises a rebirth; the renaissance of the country’s rubber industry. The ‘preacher’ is Dr Anura Dissanayake, Head of Advisory Services in the Rubber Research Institute of Sri Lanka (RRI) and a grassroots activist. In accordance with the RRI’s focus on small- and medium-sized estates (less than 50 acres), he is teaching a group of rubber farmers the correct way to plant saplings! Output and Prices Rising – and How!

|

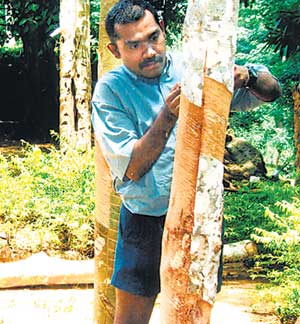

Tapping requires the most skill |

Increased tapping has been one reason for the increase in output. Under normal circumstances, the tapper does not extract latex on rainy days, which curtails his productive days to 110 per annum, 30 days being lost due to rain. With the introduction of a simple protective device called a ‘rain-guard’, his productivity goes up to 140 days, resulting in the yield increasing by 27%!

The proper application of fertilizer has also seen phenomenal results, with mature rubber plantations yielding 20% more latex than they did without fertilizer. These results have been further magnified by extending plantations to non-traditional areas, thus increasing the acreage under cultivation.

During 2004-05, Dissanayake was Chairman of the Thurasaviya Fund (under the Ministry of Plantation Industries). In that capacity, he imported milling machines that could produce 500 rubber sheets per hour. He also introduced subsidies for fertilizers and rain guard fixing.

The Economic Raison d'etre

At the recent biweekly Colombo auction, rubber – in ribbed sheets form - was traded at Rs 215 per kg. The typical farmer would get about Rs 200 per kg, with the middleman pocketing the rest. That's not a bad deal, considering that the farmer’s cost of production is just Rs 90 per kg including expenses on fertilizer, upkeep, weeding, tapping and processing.

Rubber trees have a productive life of 30 years; however, it takes nearly six years, after they are planted, for them to start yielding latex. Although hilly-and-rocky terrain can support either tea or rubber, the latter is comparatively more hassle-free. With rubber prices at current levels, rubber’s profitability per unit of land area is also higher. Industry-watchers predict that prices can only get better in future.

Times sure have changed: In the late 1990s, the price of rubber plummeted to Rs 40 per kg. Many planters underwent severe losses and sold out. But with the price having crept up to Rs 130 per kg (average: 2004) and then to Rs 150 per kg (2005), planters who stayed the course are laughing all the way to the bank. One of the reasons for higher prices is that international demand has increased, driven primarily by China’s insatiable appetite for rubber, to produce tyres and toys. Domestic demand has also been on the upswing, in tandem with the expansion of rubber-based industries.

Addressing

residual concerns

Rubber plantations commenced in Sri Lanka in 1876, with plants from Brazil. The local manufacturing industry emerged much later, in the 1950s. Two years ago, realizing the need to conserve soil and moisture, the RRI introduced ‘mukuna bractiyata’, a horizontal creeper with a spreading root. This plant enriches the soil by supplying nutrients. In addition, the RRI has also focused attention on eradicating the dreaded white root disease.

When one considers the three sets of activities – i.e. agricultural operations, tapping and processing - tapping requires the most skill. The labour force for tapping is skewed 60: 40 in favour of women. Even in the rubber industry, labour has been a problem; the younger generation has been moving away in droves, to join security firms and the garment industry.

The RRI has been encouraging the youth to join as tappers by addressing the socio-economic dimensions of the problem. With the help of systematic, two-week-long training courses, they are targeting 2,000 new tappers in the next year. They will be certified and designated as ‘LEOs’: Latex Exploitation Officers!

| || Front

Page | News

| Editorial

| Columns

| Sports

| Plus

| Financial

Times | International

| Mirror

| TV

Times | Funday Times | ST - 1 || |

| |

Copyright

2007 Wijeya

Newspapers Ltd.Colombo. Sri Lanka. |