Nutritional boost to sea cucumber industry

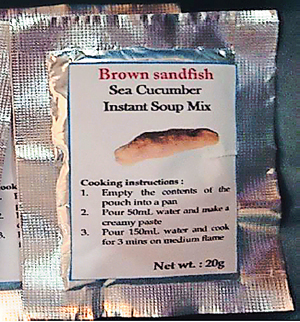

Figure 3 – Ready-to-drink soup mix

Sea cucumbers are soft-bodied, elongated, worm-like marine organisms. The catching of sea cucumbers is one of the oldest activities of commercial fisheries in Asian and Pacific countries and was introduced to Sri Lanka by the Chinese in the late 1800s. They are not usually consumed in this country but exported, mainly to Singapore, Taiwan and Hong Kong.

In Sri Lanka, sea cucumbers are caught mostly off the northern, north-western and north-eastern shores. Of the 25 species found in these waters, a total of nine commercially exploited sea cucumber species is landed on these shores using four fishing methods: Scuba diving, breath-hold diving, gleaning in shallow waters and surrounding nets. Scuba diving is the dominant fishing method, with divers fishing both day and night and reporting the highest catch rates.

Over 80% of the world harvest of sea cucumbers is processed into trepang or “bêche-de-mer” (literally “worm of the sea”). From the nutritional point of view, sea cucumbers are considered an ideal source of proteins, but with low lipids. There has been a gradual increase in both export quantities and the value of bêche-de-mer during recent years. The species and the product quality govern market demand for bêche-de-mer.

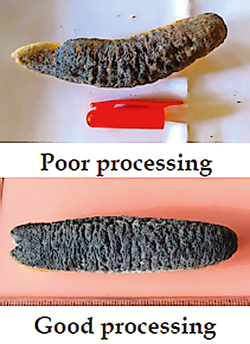

Product quality depends on the shape, appearance, colour, odour and moisture content, and is greatly influenced by the way of processing. However, this aspect is rarely addressed either locally or globally. Neither have many attempts been made to produce value-added products using sea cucumbers.

Figure 1 – Effect of processing

Analysing the effect of processing on the nutritional value of sea cucumbers would be clearly useful to enhance the quality of processed products. It is in this context that the National Research Council funded research into this area, through a grant awarded to Dr Chamari Dissanayake of the University of Sri Jayawardenapura, covering both scientific and socio-economic dimensions.

Improving current processing practices

Although a wide variety of sea cucumber processing techniques are practised in Sri Lanka, inadequate knowledge and absence of proper training on post-harvest processing have led to poor quality bêche-de-mer (Figure 1), thus losing a considerable amount of foreign income. It was demonstrated through this research that domestically processed bêche-de-mer always results in a higher percentage of moisture, crude ash and crude fat, and a lower percentage of crude protein than industrially processed products.

Processing involves evisceration (to remove internal organs), boiling, salting and drying. Various combinations of these were explored, for example the medium of boiling (sea water or fresh water with added salt); duration of boiling (low, medium and high – with differing times for each duration ranging from 3 to 20 minutes, depending on the species); type of salting (solid vs. aqueous salt); and method of drying (electric vs. sun drying). Such processing results in a reduction of the undesirable saturated fatty acids and an increase in the beneficial polyunsaturated fatty acids.

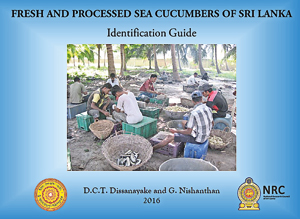

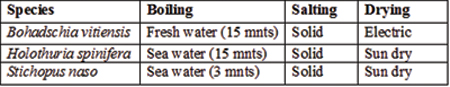

Table 1 indicates the best combinations for processing the three most prevalent types of sea cucumber species, as found from this research. These findings were disseminated in the form of posters, among both fishers and exporters, who are responsible for the processing of these species. This has made a significant impact on processing practices. The production of an identification guide for 16 sea cucumber species was another output from this project (Figure 2).

A soup to savour

Figure 2 – Identification guide for 16 species

Value addition to the sea cucumber harvest was attempted by converting it to a ready-to-drink soup mix. The highly abundant but low-value Bohadschia vitiensis species was chosen for this purpose. After evisceration and processing, the flesh was ground and sieved to obtain sea cucumber flour. This processed flour (inclusive of other natural additives) was mixed in various proportions with cornflour, and converted to a ready-to-drink soup mix. The optimum percentage of sea cucumber flour in the mix was established based on sensory tests, involving attributes such as colour, appearance, odour, mouth feel, taste and overall acceptability. A patent has been obtained for this ready-to-drink soup mix (Figure 3), and some exporters are considering the possibility of exploiting it.

Sustaining the fish and fishers

The research also involved a socio-economic survey, and discovered that fishers received typically half the export price (after processing); hence, around 48% of them showed high satisfaction towards their buyers, although 33% were dissatisfied or highly dissatisfied. Among all fishers, scuba divers registered the highest average net monthly income. However, only 11% of them had undertaken formal training and certification, leading to some health related issues.

The fishermen also expressed a very high level of dissatisfaction about the problem of rapid overexploitation of resources, in spite of management measures such as licences for sea cucumber fishing, processing and exporting. All the interviewees revealed that the sea cucumber catches had declined in terms of both size and quantity landed; and that they had to travel further and dive deeper to collect sea cucumbers; also that and many high-value species were no longer in the fishing grounds.

Given that Sri Lanka earned US$ 2.55 million in 2016 by exporting 136 metric tonnes of bêche-de-mer, it is certainly in the national interest to foster this industry, and also improve it by using the results of this study.

This research was funded by the National Research Council under grant IDG 15-50, and awarded to Dr Chamari Dissanayake of the University of Sri Jayawardenapura. Dr. Ganeshan Nishanthan obtained his doctorate on this project. Dr D.V. Pahan Prasada (University of Peradeniya) was a co-supervisor. The soup mix received a Sri Lanka Patent Numbered LK/P/1/19793.

Asitha Jayawardena was commissioned to write this article as part of the science publicity programme of the National Academy of Sciences of Sri Lanka.

Optimum processing methods for 3 species