50-year old glass company moves into new plant

Ceylon Glass Company Ltd (CGCL), a venture of the Piramal Enterprise Ltd of India, opened its new glass production plant at Horana this week and declared; “we are not a run-of-the-mill product company.” “We are no ordinary company, we don’t want to concentrate on run-of-the-mill products,” said Vijay Shah, Chairman of CGCL, speaking on the “specialty glass”, coloured bottles that the plant will manufacture at a production capacity of 250 tons a day, along with the bottles used for the liquor, cosmetics, food and beverage and pharmaceutical industries. The plant was opened by Minster of Industrial Development, Kumara Welgama. Since its inception in 1955, the CGC has been growing. Its beginnings were in Nattandiya, when the company was conceptualized by the governments of Sri Lanka and India, and the first products were hand-blown tumblers. The first furnace came in 1959 with the help of the Japanese firm, Nippon. A plant in Ratmalana was started in 1965 with an all-new 40 Tonne per-day furnace, with Nattandiya being transformed into a sand processing plant.

However “the year of turnaround” as Sanjay Tiwari, Executive Director and CEO of the CGCL said, was 2002, when the CGC was acquired by the Gujarat Glass Company. The per-day production has been 120 tons till 2005, when at this peak, steps were taken to relocate the plant to the state-of-the-art manufacturing plant in Horana. The company has invested Rs. 3.7 billion in the new plant and that has paid off with an annual growth of 20% and a market that continues to grow. Speaking about the reasons for choosing Sri Lanka to invest in, Ajay Piramal, Chairman, Piramal Enterprises, explained that as the need to expand from India arose, Sri Lanka figured because of its proximity, familiarity and the share in cultures, environments, etc. He also stressed on the strong and skilled workforce as well as supportive local authorities. Along with 200 skilled workers brought in from India for the construction, the new plant will generate 500 job opportunities. Also, as Piramal stressed, this is an excellent opportunity for a company from the East to take a significant place in an industry that is dominated by the ‘Superpowers’.

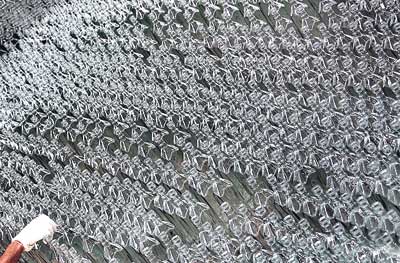

Touring the factory was an experience. A silver fume-chimney reaches as high as a good 25-30 feet emitting the refuse gases away from the plant, sunlight glints off the piles of glass outside and minute sand-like glass crunches underfoot. The factory is a maze of machines and this was a rare opportunity to watch the production of glass liquor bottles. What you see at first is a glowing orange-red ember in the shape of a bottle being brought out by a mechanical “arm”. What you see a second later is a fully formed glass bottle being rammed down on the counters. There is even a process to widen the bottleneck to fit the funnels through which the companies pour the drink into bottles. Defectives are picked out and discarded. Speaking on the challenges faced by a project of this magnitude, the Piramal Chairman mentioned the rising fuel costs and the conflict situation which hamper progress immensely. |

|

||

| || Front

Page | News

| Editorial

| Columns

| Sports

| Plus

| Financial

Times | International

| Mirror

| TV

Times | Funday Times || |

| |

Reproduction of articles permitted when used without any alterations to contents and the source. |

© Copyright

2007 | Wijeya

Newspapers Ltd.Colombo. Sri Lanka. All Rights Reserved. |